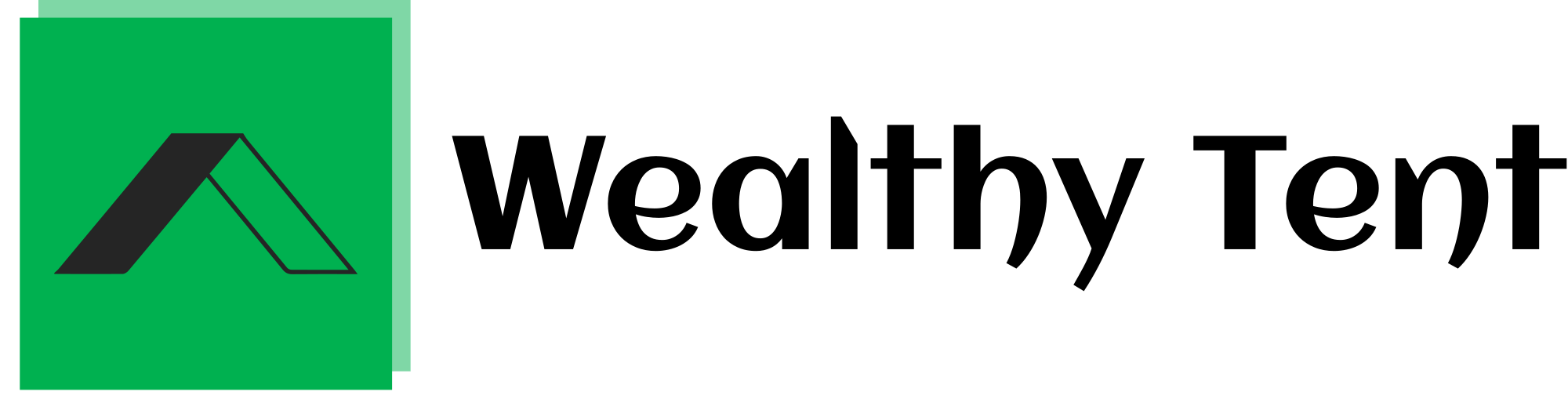

Best Manufacturing AI Quality Tools: A Complete Guide to Smart Factory Inspection Systems

Manufacturing AI quality tools have revolutionized modern industrial production, setting new benchmarks for precision and efficiency in factory operations worldwide.

Smart factories now leverage sophisticated artificial intelligence systems that can detect microscopic defects invisible to the human eye, ensuring unprecedented quality control standards.

The integration of manufacturing AI quality tools represents a quantum leap forward in how businesses approach quality assurance, combining real-time monitoring with predictive analytics.

This comprehensive guide explores cutting-edge inspection systems that are reshaping the manufacturing landscape, from automated visual inspection to advanced predictive maintenance.

We strongly recommend that you check out our guide on how to take advantage of AI in today’s passive income economy.

Table of Contents

Understanding Manufacturing AI Quality Tools

Modern manufacturing facilities are witnessing a dramatic transformation as manufacturing AI quality tools become increasingly sophisticated and accessible to businesses of all sizes.

These intelligent systems utilize complex algorithms and machine learning capabilities to analyze production processes with remarkable accuracy and consistency.

The fundamental components of manufacturing AI quality tools include computer vision systems, deep learning models, and real-time analytics platforms that work in perfect harmony.

At their core, these systems are designed to eliminate human error while significantly improving production speed and efficiency across the manufacturing floor.

Core Components of AI Quality Control

Advanced manufacturing AI quality tools comprise several essential elements that work together to create a comprehensive quality control ecosystem.

Computer vision systems equipped with high-resolution cameras capture detailed images of products at various stages of production.

Deep learning algorithms process these images in real-time, comparing them against vast databases of known defects and quality standards.

Neural networks within the manufacturing AI quality tools continuously learn and adapt, becoming more accurate with each inspection cycle.

Real-World Applications and Implementation

The practical implementation of manufacturing AI quality tools spans across various industries, from automotive manufacturing to electronics assembly.

These systems excel in identifying surface defects, dimensional inconsistencies, and assembly errors with precision that far exceeds traditional inspection methods.

Leading manufacturers have reported significant improvements in quality metrics after implementing smart factory inspection systems.

Success stories demonstrate how manufacturing AI quality tools have reduced defect rates by up to 90% while increasing production speeds.

Industry-Specific Solutions

Automotive manufacturers utilize specialized manufacturing AI quality tools to inspect paint quality, panel alignment, and welding integrity.

Electronics manufacturers employ these systems to examine circuit board assemblies and component placement with microscopic precision.

Pharmaceutical companies rely on AI-powered inspection systems to ensure medication quality and packaging integrity.

Food and beverage producers use manufacturing AI quality tools to maintain strict quality standards and detect contamination risks.

Advanced Features and Capabilities

Modern manufacturing AI quality tools incorporate advanced features that extend beyond basic inspection capabilities.

Predictive maintenance algorithms analyze equipment performance data to prevent potential failures before they occur.

Real-time monitoring systems provide instant alerts when quality parameters deviate from established standards.

Integration with IoT sensors enables comprehensive data collection and analysis across the entire production line.

Data Analytics and Reporting

Sophisticated manufacturing AI quality tools generate detailed reports and analytics that drive continuous improvement initiatives.

These systems track key performance indicators (KPIs) and produce actionable insights for process optimization.

Historical data analysis helps identify patterns and trends that might impact product quality over time.

Advanced visualization tools make complex data easily accessible to stakeholders at all levels of the organization.

Implementation Strategies and Best Practices

Successful deployment of manufacturing AI quality tools requires careful planning and a structured approach to implementation.

Organizations must first assess their specific needs and identify key areas where AI inspection can provide the most significant benefits.

Staff training and change management strategies play crucial roles in ensuring smooth adoption of new technologies.

Regular system updates and maintenance ensure optimal performance of manufacturing AI quality tools over time.

Integration Considerations

Seamless integration with existing manufacturing execution systems (MES) is essential for maximizing the benefits of AI quality control.

Companies must ensure compatibility between manufacturing AI quality tools and their current production equipment.

Data security and privacy considerations should be addressed during the implementation phase.

Cloud connectivity and edge computing capabilities need to be evaluated based on specific operational requirements.

Economic Impact and ROI Analysis

Implementing manufacturing AI quality tools represents a significant investment that delivers substantial returns through improved quality and reduced waste.

Companies typically see ROI within 12-18 months through reduced labor costs and improved production efficiency.

The long-term economic benefits include enhanced brand reputation and increased customer satisfaction.

Case studies show that manufacturing AI quality tools can reduce quality-related costs by up to 60%.

Cost-Benefit Analysis

Initial investment in manufacturing AI quality tools varies based on system complexity and scale of implementation.

Operating costs decrease significantly as AI systems reduce the need for manual inspection and quality control personnel.

Reduced scrap rates and warranty claims contribute to overall cost savings.

Enhanced production speed and efficiency lead to increased revenue opportunities.

Future Trends and Innovations

The future of manufacturing AI quality tools points toward even more sophisticated and autonomous inspection systems.

Emerging technologies like quantum computing and advanced AI will further enhance the capabilities of these systems.

Integration with augmented reality (AR) will provide new ways for operators to interact with quality control systems.

Next-generation manufacturing AI quality tools will offer predictive capabilities that anticipate quality issues before they occur.

Emerging Technologies

5G connectivity will enable faster data processing and real-time decision-making in manufacturing environments.

Advanced sensor technologies will provide even more detailed data for quality analysis and control.

Machine learning algorithms will become more sophisticated, leading to improved accuracy and reliability.

Edge computing capabilities will enhance the speed and efficiency of manufacturing AI quality tools.

Conclusion

The adoption of manufacturing AI quality tools represents a fundamental shift in how modern factories approach quality control and inspection.

These sophisticated systems continue to evolve, offering increasingly powerful capabilities for ensuring product quality and consistency.

Organizations that embrace these technologies position themselves at the forefront of manufacturing innovation and excellence.

The future of smart factory inspection systems promises even greater advances in accuracy, efficiency, and automation.

Final Recommendations

Companies should begin their journey toward AI-powered quality control with a clear strategy and implementation plan.

Regular evaluation and updates of manufacturing AI quality tools ensure optimal performance and ROI.

Continuous staff training and development programs maximize the benefits of these advanced systems.

The investment in quality control automation today will pay dividends in operational excellence tomorrow.

We strongly recommend that you check out our guide on how to take advantage of AI in today’s passive income economy.